Key Developments in the History

of Gravity Dams

|

Ancient Times |

The Roman Empire

Emperor Nero (AD 54-68) had a 40 m high, 13.5 m wide, and 80 m lonldam built for a pleasure

lake near his villa at Subiaco, Italy. The dam was one of the earliest Roman dams and

remained the highest the Romans ever built. Moreover, the Subiaco dam and two smaller

dams nearby are the only Roman dams in Italy. Although the dam was to thin, it remained

intact until it failed in 1305. Records blace the blame on two monks who took it upon

themselves to remove stones from the dam, apparently in an attempt to lower the level of

the lake which was flooding their fields.

Inside a monastary near the dam hangs a painting from 1428 showing St. Benedict

fishing from the crest of the Subiaco Dam. Incedentally, this painting is the oldest

surviving illustration of a dam.

|

Painting of the Subiaco Dam

photo from Schnitter

courtesy of

A.A. Balkema (#)

|

|

In extreme contrast to the number of Roman dams in Italy, Roman gravity dams were

abound in the Iberian peninsula, North Africa, and the Middle East. The largest

reservoir impounded by the Romans was created by a dam located near Homs, Syria in

284 AD. The dam had the extraordinary length of 2000 m and impounded approximately

90 million m3 of water. The main body of the dam consisted of concrete

lined by masonry on both slightly inclined faces and on the crest. It was also grossly

overdesigned: in its central part, the dam was 7 m high and 14 m wide . The crest width

was smaller, but still measured 6.6 m for the upper 1.3 m of height.

|

Typical Roman Gravity Dam

photo from Schnitter

<

courtesy of

A.A. Balkema (#)/i>

|

|

Later Dams

The record height of the Roman Subiaco dam wasn't broken until 1594 with the construction of

the 46 m high Tibi dam in Spain. However, the Roman concept of a rectangular wall was mostly

maintained, with only a few, hesitant attempts to use trapezoidal, let alone the correct

triangular, cross sections. The use of concrete by the Romans for the dams' interior or

as a building material in general, fell into oblivion, while the construction techniques

essentially remained the same: pick and shovel.

|

Evolution of the Modern Gravity Dam

|

|

The Correct Shape

In 1765 and 1800, the first triangular gravity dams were built in Mexico. Unfortunately, it

remains unknown who their ingenious builder was. Amazingly, he/she had adopted the modern

shape almost one century before it was developed in France.

In 1850, French engineer J. Augustin Tortene de Sazilly (1812-1852) showed in a

lecture that the most advantagous profile for a gravity dam is triagle with a verticle

upsteam face. Sazilly also analyzed three recent French navigation dams in a paper

published posthumously in 1853. He used the cross sections of these three dams to

illustrate the confusion and uncertainty in the design of gravity dams. In fact,

two of the dams were wrongly inclined on the upstream side!

|

The Triangular Gravity Dam

sketch from Schnitter

courtesy of

A.A. Balkema (#)

|

|

Materials: The Return of Concrete

Concrete--now on the basis of Portland cement--was used for the first time since the

Romans for the Boyds Corner gravity dam completed in 1872 in New York. The Lower

Crystal Springs Dam in California, completed in 1890, was the first dam in which

the water content of the concrete was specifically controlled. Because the cement

industry was nonexistent in California, the cement had to be imported from England.

In 1892 in France and in 1918 in the United States it was scientifically determined

that by decreasing the amount of water in concrete and increasing the amount of

cement, the stronger it is. However, a minimum amount of water must be there to

ensure the workability of concrete while the amount of cement may need to be limited on

account of the heat it develops during the hardening process.

|

The Lower Crystal Springs Dam

photo courtesy of

the San Francisco Public Utilities Commission

|

BIG Gravity Dams: New Ideas in Construction!

|

|

Hoover Dam

The next big development was the construction of the Hoover Dam, built by the US

Bureau of Reclamation. It was a quantum jump in dams. Not only was it 60% higher

and 2.5 time larger than any any dam in existence, but it was also to impound the

unheard of quantity of 38,550 million m3 of water. The dam was built between

1931 and 1936 and was designed as a curved gravity dam. Concreting the Hoover Dam barely

took two years with some 5000 men placing up to 8000 m3 of concrete per day!

|

The Hoover Dam

photo from US Bureau of Reclamation

(#)

|

|

Grand Dixence Dam

The tallest of the concrete gravity dams is the Grande Dixence dam in the Swiss Alps

constructed from 1951 to 1962. It's 285 m high!

|

The Grand Dixence Dam

photo from VSE

|

Latest Ideas in Gravity Dams

Steel

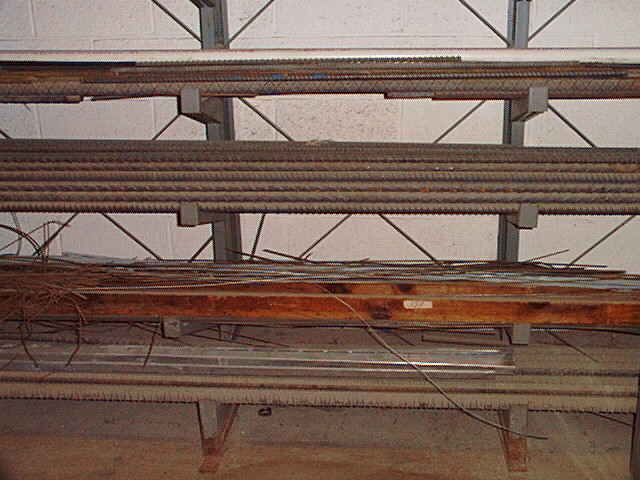

A relatively new development in the construction of gravity dams is incorporation of

post-tensioned steel into the structure. This helped reduce the cross section of Allt

Na Lairige Dam in Scotland to only 60 percent of that of a conventional gravity dam of

the same height. A series of vertical steel rods near the upstream water face, stressed

by jacks and securely anchored into the rock foundation, resists the overturning

tendency of this more slender section. This system has also been used to raise

existing gravity dams to a higher crest level, economically increasing the storage

capacity of a reservoir. However, since reaching their prime in the 1960s, gravity

dams have become something like a dying species, the dinosaurs of an era which

especially the idustrialized countries with their high labor cost no longer can afford.

|

Steel Rods

photo by Megann

Polaha (#)

|

|